How Engine Cooling System Works

Posted in: Driving Tips.

How Engine Cooling System Works

The engine is an important part of your vehicle, it is saddled with the responsibility of generating power to get your car –and you – moving. To do this, it burns fuel to operate and in the process generates heat. To sustain the vehicle engine’s operation as well as ensure peak performance of your vehicle, it is necessary to keep the engine running at the optimum operating temperature range and this is where the engine cooling system becomes important.

Are you interested in how engine cooling system works? Read on and learn how you can keep your engine working properly so you don’t weld the piston rings to the engine cylinder walls.

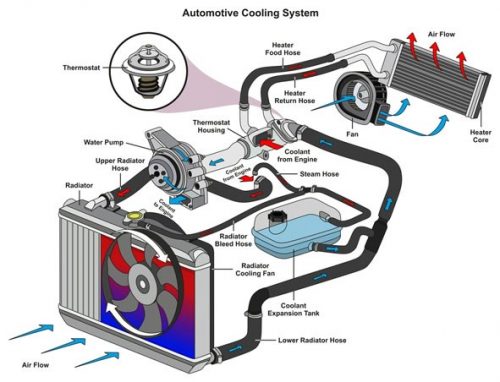

The Components of a Cooling System

The Radiator

The radiator’s job is to release heat generated from the engine into the surrounding. It is usually made up of flattened aluminium fins and a plastic top or, in older car models, a copper core and a brass top. It has various parts, which include inlet and outlet port, pressure cap, and drain plug.

Radiator Cooling Fans

The radiator is equipped with fans that help force cool air through the radiator fins. The fans can be one or two, but they all have a cover designed to protect fingers and direct airflow. On older models, the fan comes on whenever the engine is running, but for newer models, the fan is controlled by a computer which varies the fan speed depending on the temperature of the engine.

Pressure Cap & Reserve Tank Water

As the engine temperature rises from the initial starting temperature, the temperature of the coolant circulating around the engine block also increase, which leads to expansion of the coolant liquid. Since this expansion takes place in a sealed system, the internal pressure will increase allowing the coolant to safely reach a temperature of 240 degrees without boiling.

If the pressure keeps increasing, the valve within the pressure cap releases some coolant into the reserve water tank. This right here is one reason why you should only fill this tank to the recommended maximum if you do fill past the marked line, chances are your coolant will be wasted when the liquid level starts to increase.

Coolant Temperature Sensor

The name alone should give you an idea of what this component does, it is a temperature-sensing device that serves the purpose of reading the engine temperature. This is the component that provides the necessary data used by the vehicle’s computer to control the operation of the radiator fan, optimize the fuel injection and ignition timing of the engine, and the source of the engine temperature reading displayed at the driver’s console.

Pump

The pump serves the same purpose as the heart – circulate the coolant. Within its casing is a radial impeller which, with the help of a serpentine belt, is driven by the engine’s rotational motion. Provided the engine is running, the pump will keep the coolant circulating.

Coolant

Technically speaking, the coolant is not considered a part of the cooling system. But, this is what makes engine cooling a possibility. If the pump is considered the heart of the cooling system, then the coolant will be the blood, without it the pump is useless. It could be in gas or liquid form. As it circulates the engine, it absorbs heat generated and transfers the heat to the radiator to get rid of.

Thermostat

The thermostat is simply a valve that checks the temperature of the coolant and allows it to flow through to the radiator only when a certain temperature value has been exceeded. What this means is that when you first start your engine, the coolant circulates the engine (to avoid hot spots) until the engine has warmed up to an efficient operating temperature, only then is the coolant allowed to flow through to the radiator and shed off the heat.

Bypass System

The bypass system is just what it sounds like. It’s a passage that redirects the coolant towards the pump instead of flowing to the radiator. When the engine is just starting and its temperature is not up to the efficient operating temperature, the thermostat closes so the coolant can be re-circulated around the engine without losing heat at the radiator.

Hoses

Since the coolant has to leave its storage container and flow through the pump, engine block, and radiator, it needs a connecting circuit and that’s what the hose does, connect these separate parts.

Most vehicles make use of high-temperature-resistant rubber, but some engines have a built-in passage in the front housing or make use of a metal tube. Either way, they are all designed to withstand the pressure within the cooling system. If you notice the rubber beginning to look cracked and dry, or becomes spongy and soft, or some ballooning at any of the ends, then it is time to get them replaced.

Putting it all together

As soon as you ignite the engine and the pistons start moving, heat is generated. From the piston movement, the coolant pump gets its power source to circulate the coolant around the engine block.

Assuming the engine was at a very low initial temperature, the thermostat blocks the coolant from flowing through to the radiator (where it would have lost heat), channelling the now warm coolant back to the pump which re-circulates it.

When the coolant temperature is at the optimum, the thermostat allows it to flow through to the radiator to maintain that operating temperature.

There is no trick to keeping your engine temperature at the optimum range. If the system is faulty it will overheat. The most important maintenance tips are simple: ensure the coolant is at the recommended level before driving off, flush and refill the coolant periodically, and inspect the hoses and belts for leaks or signs of weakness.

Tags: How Engine Cooling System Works